Get Replacement Parts Fast with Our Reverse Engineering Services

Whether your part has been discontinued or the waiting period for a replacement is impractical, Baillie Fabricating & Welding’s reverse engineering experts can step in to fill the void.

Here are a couple of case studies highlighting our reverse engineering services.

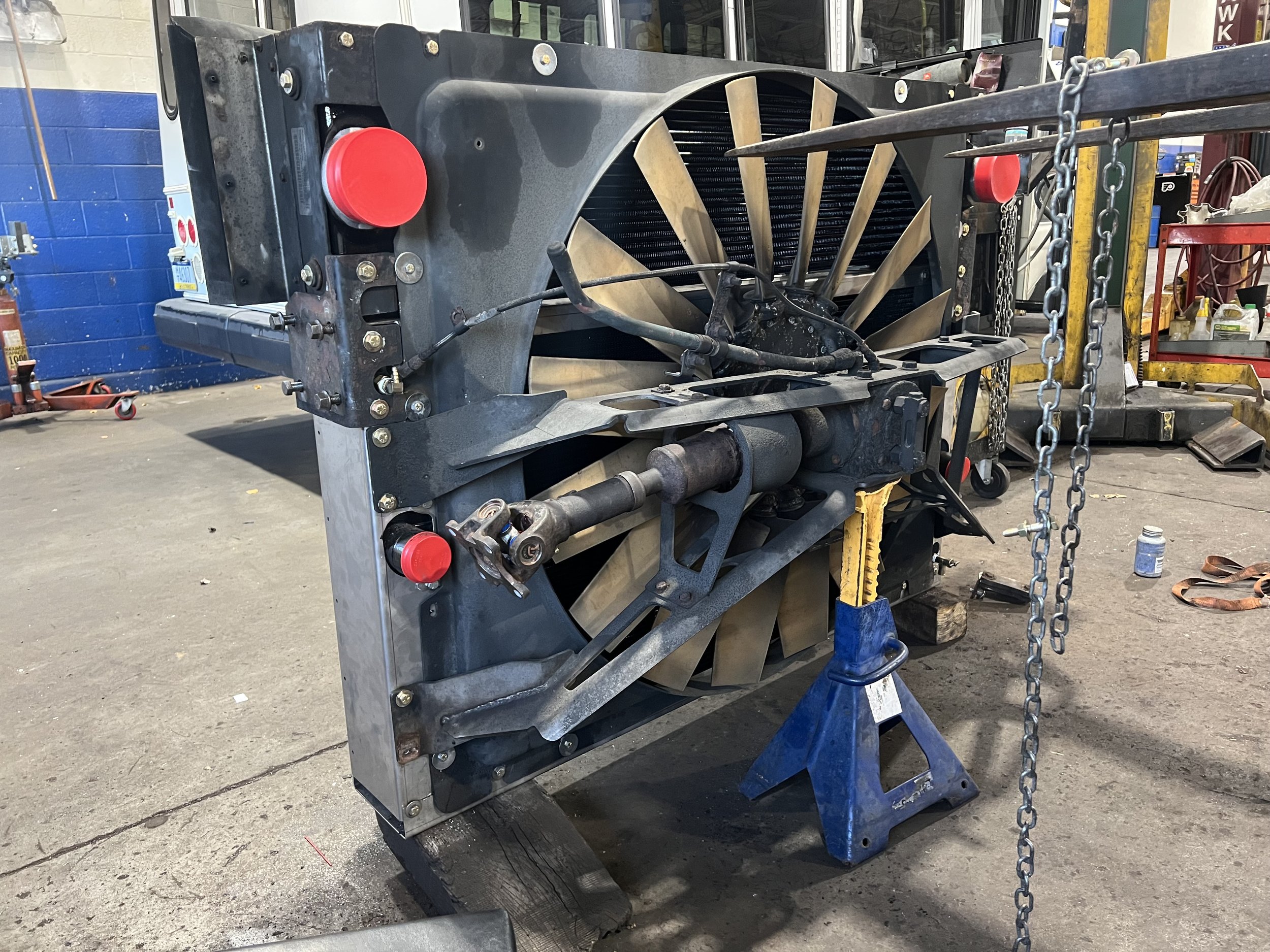

Case Study: Reverse Engineering a Radiator Housing

A prominent Pennsylvania bus company approached us with a unique challenge involving one of their buses, which urgently needed a replacement radiator housing. The original part was severely rusted, and sourcing it from the original manufacturer would require a wait time of six months—an impractical delay for a vital transportation service.

Our approach

We began by examining the deteriorated housing and the radiator to understand the exact specifications and constraints. Recognizing the rust issue, we opted for stainless steel over the original regular steel. This decision not only promised a longer lifespan for this specific part but also addressed the recurring issue of rust the customer had faced with other parts.

Our Pennsylvania metal fabrication pros meticulously measured and sketched the housing, creating a prototype from scrap steel for trial fitting. The customer’s mechanics played a crucial role, bringing in the actual mounting brackets used in the buses to ensure precise compatibility.

Challenges and solutions

The housing needed to fit within a specific location on the bus and accommodate the radiator perfectly. Our team navigated this challenge by engaging in an iterative design process, involving several rounds of drafting and adjustments.

The housing also incorporated a complex array of holes and nuts for mounting brackets. We worked closely with the bus company's mechanics, who provided invaluable insights into the bus's fitting requirements, ensuring that our final design was a perfect match for their fleet.

Outcome

The bus company was thrilled with the results! Our ability to reduce the lead time from six months to just one week not only provided them with high-quality, durable radiator housing but also significantly minimized downtime for their bus, ensuring uninterrupted service.

Case Study: Reverse Engineering an Industrial Equipment Component

An original equipment manufacturer (OEM) specializing in industrial machinery faced a critical production halt due to a failing component with complex, metric dimensions. The original part supplier was no longer in business, and alternative suppliers quoted extensive lead times.

Our solution

We meticulously reverse engineered the component, paying close attention to its unique features and specifications.

Originally made of anodized aluminum, the part posed a challenge as anodizing this part would not be cost effective. However, we collaborated with the customer to opt for an un-anodized aluminum alternative. Despite not having original drawings, our knowledge of the application and pressure requirements guided us in choosing the appropriate aluminum grade.

Our team manufactured several parts, allowing the client to build a small inventory for future needs.

Results

The components we crafted met all of our customer’s specifications and functional requirements, seamlessly integrating into their machinery.

The OEM was exceptionally pleased with our quick turnaround and the quality of the replicated parts. They expressed their intent to send more parts for reverse engineering, highlighting their confidence in our capabilities.

Reverse Engineering Services at Baillie Fab

At Baillie Fabricating & Welding, we pride ourselves on our ability to bring old or unavailable parts back to life, ensuring they meet or exceed their original functionality. We infuse every reverse engineering process with these solution-oriented approaches:

Technical proficiency. Our team's skill set includes precision measurement with micrometers and calipers, understanding both standard and metric systems, and the ability to conceptualize the original engineering of the part.

Material selection. We carefully select materials based on the part's application, load-bearing needs, and environmental resistance. Upgrading materials is a common practice to enhance the part's durability.

Attention to detail. Every reverse engineering project at Baillie Fab prioritizes the crucial elements of the job. Whether it's ensuring bolt-hole patterns align perfectly or deciphering thread sizes, our attention to detail is unmatched.

Challenges and limitations for cast parts

Reverse engineering cast parts can be particularly challenging due to the complexities of replicating casting processes. While we strive to repair or recreate these parts, some limitations in strength and cost may arise. However, our team is dedicated to exploring all possible avenues to deliver the best results.

Bring Your Parts to Baillie Fab

Reverse engineering is more than just a replication process; it's an opportunity to improve upon the original design, adapting it to current needs and technologies.

If you're facing challenges with a part that's no longer available or have been quoted an unreasonable lead time, bring your part to our Pennsylvania metal fabrication experts. With our team’s superior reverse engineering services, you’ll receive the solution you need with the expertise and precision you deserve.